Water hammer arrestor not working? Keep reading to learn how to fix this issue without calling a professional plumber.

Good practices for preventing water hammer

Although not as bad as a burst pipe, water hammer is a plumbing issue you cannot ignore.

On the one hand, it’s annoying to hear that noise whenever you are using your fixtures.

On the other hand, dealing with water hammer means something’s wrong with your plumbing system. Ignoring this phenomenon can lead to more severe plumbing issues.

Simply installing a water hammer arrestor may not be sufficient.

Many people complain about water hammer arrestor not working.

If you are dealing with recurring water hammer, you should make a thorough check of your pipes. You need to discover the actual cause of the hydraulic shock. Next, make sure you install the arrestor in the right place.

More than that, it’s important that you adhere to some simple yet highly effective good practices to prevent water hammer.

In this post you have everything you need to know to solve the problem.

What is water hammer?

The following situation is quite common: you turn off a tap and you hear pipes clanging. This is water hammer or hydraulic shock.

What happens is that when water hits a sudden stop inside pipes, it lashes back and creates a shockwave. To understand better, consider the most common causes of water hammer:

Some appliances

Have you just installed a new washing machine or dishwasher and now you are dealing with water hammer?

The problem is these appliances have a water supply controlled by solenoid valves. Being electrically controlled, they stop the flow of water immediately. Having no other place to go, water with high pressure goes back into the pipe causing a loud bang.

Air chambers absorb extra pressure in your system; if blocked with water or other residues, they stop working.

Water ripples from your tank

When water flows into the tank, the float valve moves up and down, closing and opening the valve. This can create waves that echo along the pipes, causing water hammer. The use of a reinforcing metal plate will stop this movement in plastic water tanks.

Loose pipes

Pipes that are not secured tightly to a sturdy surface can amplify water hammer considerably.

Ways to prevent water hammer

Now that you know what water hammer is, it’s time to look at ways to prevent it. Aside from eliminating the unpleasant noise, you will also be protecting your piping systems and avoid unnecessary wear and tear.

The use of air chambers

If you live in a newer home, your plumbing system probably has a solution for water hammer already incorporated. Most commonly, it’s air chambers or vertical pipes installed behind valves. Filled with air, these air chambers act as a cushion when water hammer occurs.

While generally effective, this solution may not be permanent. Water can get into the air chambers, causing them to malfunction. The fix is simple – empty your plumbing system of water and air chambers will automatically refill with air.

Reducing water pressure

Even with air chambers, hydraulic shock may still occur if your home’s water pressure is too high. A water pressure gauge available in most hardware stores can help you determine your water pressure at home.

Is your water pressure too high (over 50 psi)? You can either install a water pressure regulator or ask the water utility company to lower it. [1]

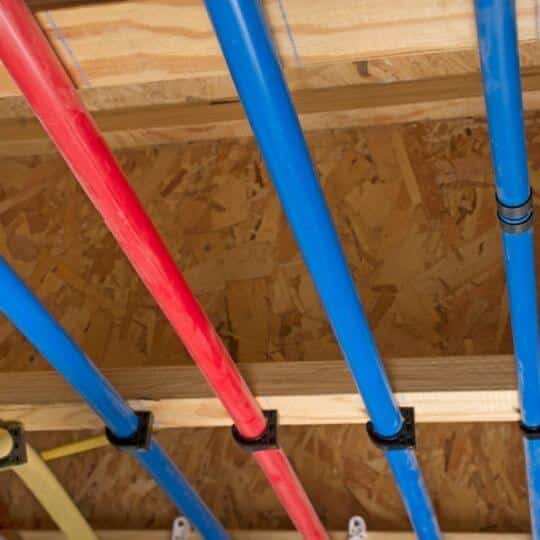

Fixing your pipes in place

It’s important to make sure your pipes are mounted securely and fixed in place. Pipes that are not properly secured will shake freely when water runs through them, amplifying water hammer.

Pipes should be attached to a firm, stable surface and secured at every two yards the least. Add more pipe straps, if necessary, preferably padded ones that offer additional vibration reduction.

- Cushioning water supply lines

- Pipe insulation is available in foam tubes, fitting around water supply lines to prevent them from banging.

- They are very easy to install as they come pre-split from end to end. All you need to do is open the tube with your finger and fit it over the pipes.

- Installing a water hammer arrestor

One of the best solutions to get rid of hydraulic shock is installing water hammer arrestors. These air-filled cylinders will absorb the additional water pressure each time a valve suddenly shuts off.

Keep on reading to find out how to install a water hammer arrestor and what to do with a water hammer arrestor gone bad.

How to use a water hammer arrestor to get rid of hydraulic shock?

A water hammer arrestor is an improved air chamber. This device includes a chamber filled with gas or air, sealed with a piston. The piston separates the water and the gas or air.

Water hammer arrestors are installed near the shutoff valve responsible for the hydraulic shock.

Installing a water hammer arrestor is simple. The difficulty level of this job depends on the type of arrestor you choose. However, this operation can be easily done without advanced plumbing skills.

Here are the main steps you need to follow:

- Turn off water

- You can shut off water to the area where you experience water hammer or, even better, in the entire house. For installing multiple water hammer arrestors, shut off the entire water supply.

- Prepare for some mess

- Keep a bucket and old towels nearby to collect water and debris.

- Disconnect hoses

- Use an adjustable wrench or tongue-and-groove pliers to turn hose fittings loose.

- Wrap the thread seal tape

- Wrap the male end of each shutoff valve with thread seal tape. Do the same for the male threads of the water hammer arrestor.

- Install the water hammer arrestor

- The actual operation depends on the type of water hammer arrestor you have chosen. If the arrestor is threaded, you need to thread the device onto each inlet. For compression fittings, place the compression ring against the valve and tighten.

- There are also push-fit water hammer arrestors that are simply fitted firmly onto the pipe.

- Connect hoses back

- Connect the water supply tube to the water hammer arrestor and tighten the connection with pliers or a wrench.

- Test the water hammer arrestor

- Turn the water supply on and see if the water hammer is gone. Run the appliance on a water hammer arrestor for one test cycle. Also remember to look for leaks using a flashlight.

Water hammer arrestor not working – how can you fix it?

Water hammer arrestors are very effective when installed correctly. It’s also vital that you choose the right size and place it close to the appliance causing the water hammer.

Even so, some homeowners complain about their water hammer arrestor not working. The cause for recurring water hammer can be a water hammer arrestor gone bad.

A water hammer arrestor should not malfunction after a few weeks of use. They generally work fine for at least three years. If your water hammer arrestor is older than three years, it could be defective.

One cause of a water hammer arrestor gone bad is the mechanical wear of its parts. It happens with any fixture that has moving parts.

The other main cause for water hammer arrestor not working is the device getting waterlogged.

Air is absorbed into the water and the air chamber no longer does its job to provide a cushion.

The water hammer arrestor can fail to work if water pressure is too high. With water pressure higher than 50 psi, the arrestor will not be able to do much to halt the hydraulic shock.

Before buying a new water hammer arrestor, try the two following simple solutions:

Adjust the water pressure reduction valve

Look for the pressure-reducing valve near the home’s main water supply. Adjust the pressure at 50 or below. These valves either have an adjustable handle or are operated with a wrench.

Check for loose water supply lines

When straps securing pipes are not tight enough, you can replace or add some more to prevent vibration. Keep in mind that metal straps do not go with copper pipes, as the mixture of materials causes electrolysis.

If these two fixes don’t work, the water hammer arrestor has probably gone bad and you need to replace it.

To Sum Up

The answer is yes, they do work. However, you need to make sure they are placed in the right spot and installed correctly.

Aside from using a water hammer arrestor, you should also consider the other prevention methods presented above. A water hammer arrestor not working is not necessarily defective, but possibly not able to deal with situation.

Michael Davis is a heating & plumbing expert who currently works as independent contractor in SC. He also writes for Plumbertip.

For almost 10 years he worked on various plumbing tasks across South Carolina.