What are the exact differences between PEX vs Polybutylene piping materials?

Installing piping in homes requires ample knowledge to avoid plumbing problems. Choosing the right plumbing pipes is crucial for ensuring that your plumbing system works efficiently.

Innovative pipeline technologies such as plastic pipes have effectively replaced traditional pipes like copper due to their corrosion resistance and flexible nature.

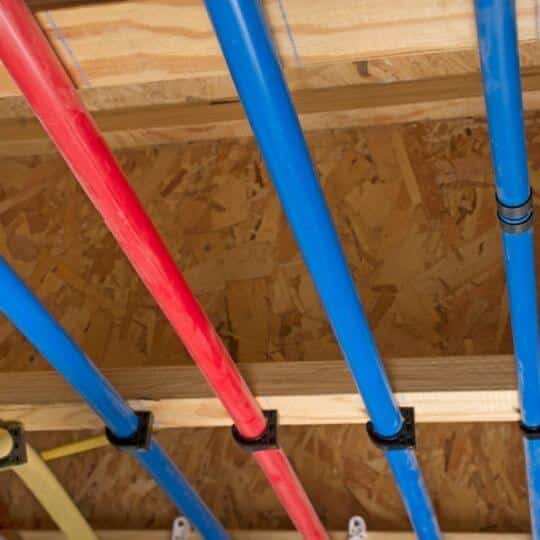

There are two popular options for such plastic pipes: PEX (cross-linked polyethylene) and polybutylene (PB). PEX and PB are two distinct plastic pipe types with unique characteristics.

Polybutylene is plastic piping material commonly used between 1978 and 1995. But due to severe issues associated with PB pipes, their installation has become illegal in most states.

However, there has been a significant shift in recent years in the plumbing industry toward replacing PB piping with PEX. This article will explore the differences between PB and PEX piping and highlight why transitioning from PB to PEX is prudent for homeowners.

Difference Between PEX vs Polybutylene

Polybutylene pipes were made from a polybutylene polymer. They gained popularity in the late 1970s.

This was due to their flexibility, cost-effectiveness, and freeze resistance. These pipes were widely used in residential and commercial plumbing applications [1].

The flexibility of polybutylene pipes made them suitable for navigating tight spaces and reduced the need for additional fittings and connections. The benefits of polybutylene pipes included resistance to chemical corrosion, which made them less prone to corrosion.

The pipes also offered quieter operation because of the reduced water hammer phenomenon compared to pipes of other materials.

Their relatively low-cost installation made them attractive for construction projects with budget constraints. Regrettably, PB pipes were not widely embraced due to their attribute of weakness which resulted in user losses.

Conversely, PEX pipe is a reliable pipe made from High-Density Polyethylene (HDPE), which is a durable and flexible material. One of the significant advantages of PEX pipes is their flexibility, which allows for easy installation, especially in tight spaces.

It has been successfully utilized worldwide for numerous years and is the preferred plumbing choice for residential purposes. However, it is not suitable for outdoor use because such pipes become damaged if exposed to UV rays.

The primary distinction between PB and PEX lies in their manufacturing processes. PEX undergoes a cross-linking of polymer chains, which enhances its material properties. In contrast, PB pipes lack this cross-linking process.

The cross-linking process in PEX improves material characteristics, making it highly advantageous. One significant advantage of PEX over PB is its ability to withstand higher water pressure.

Despite attempts by PB manufacturers to demonstrate its superiority, PEX consistently exhibits greater pressure tolerance. Thus PEX surpasses PB as a preferable option for domestic plumbing applications.

PEX pipes remain widely accepted in many countries due to their long-lasting properties, which offer both time and cost savings to consumers. Its installation process often involves using fewer fittings, thereby reducing the chances of leaks and increasing overall system efficiency.

PEX pipes are highly resistant to freezing and bursting. Since they are flexible, they can expand and contract without sustaining damage. This makes them ideal for colder climates where freezing is a concern.

PEX pipes exhibit remarkable longevity and durability, often outlasting traditional materials like copper or galvanized steel. Their resistance to corrosion and scaling ensures a consistent water flow throughout the plumbing system. Moreover, PEX pipes are cost-effective, both in terms of material and installation costs.

The Need to Replace Polybutylene (PB) With PEX Piping.

Polybutylene pipes, once praised for their affordability and ease of installation, have encountered numerous challenges and failures over time. As a result, replacing these pipes has become a common practice in buildings affected by its issues.

Polybutylene pipes have a significant drawback. For example, they react with chlorine used in the purification of water.

Over time, chlorine gradually weakens the bonds of PB pipes, rendering them susceptible to breakage under water pressure. This reaction causes the material to become brittle, which results in pipe failures [2].

The pipes’ vulnerability to temperature fluctuations exacerbates the problem. As they expand and contract, the already brittle material is weakened over time. In contrast, PEX exhibits superior resistance to chlorine and can effectively handle high water pressure.

Problems with Polybutylene Piping

- Degradation over Time

Polybutylene pipes have faced significant challenges in terms of aging and degradation. Studies have shown that exposure to oxygen causes a chemical reaction to occur within the pipes. This leads to cracking and corrosion and premature failure of these pipes [3].

Also, cracks and corrosion eventually result in leaks and significant water damage within the home. This has resulted in widespread issues and costly remediation efforts in buildings where polybutylene pipes were installed.

PB piping is also susceptible to temperature fluctuations. When exposed to heat or direct sunlight, the pipes expand and contract, making them more prone to bursting.

- Health Concerns

PB piping has been found to leach a toxic chemical known as bisphenol-A (BPA) into the water supply. As the molecules in the pipe break down, they release BPA, which can pose severe health risks to individuals [4].

These risks range from an increased likelihood of developing cancer to the potential for congenital disabilities.

- Difficulty in Finding Replacement Parts

Since PB piping has been banned in most states, finding replacement parts for repairs can be challenging. This scarcity of replacement parts increases costs and prolonged repair times for homeowners.

Moreover, due to the potential risks associated with polybutylene pipes, their use has significantly declined. This means that finding professionals experienced in working with this material can be challenging as well.

- Home Insurance Challenges

Because of recognized problems and the potential for failure, many insurance companies consider polybutylene to be a high-risk plumbing material.

As a result, some insurance companies may refuse to cover homes with PB pipes or impose higher premiums. This might make it difficult for homeowners to acquire appropriate and adequate insurance coverage [5].

Advantages of PEX Piping

- Easy Installation

Both PEX and polybutylene pipes have advantages in terms of ease of installation. PEX pipes, with their flexibility, are easy to maneuver and require fewer fittings, which reduces the chances of leaks. But unlike PB, PEX piping does not require gluing or soldering.

Specialized tools, such as crimping or expansion rings, create secure connections. This simplifies and speeds up the installation process and makes it a cost-effective option for plumbing projects.

- Flexibility

PEX piping boasts high flexibility, making it less prone to cracking. This flexibility is particularly beneficial in homes with freezing temperatures, as PEX pipes are less likely to break under extreme conditions.

- Performance and Durability

Several factors come into play when comparing the performance and durability of PEX and Polybutylene pipes. PEX pipes exhibit excellent resistance to corrosion and scaling, ensuring a long lifespan with minimal maintenance.

Additionally, PEX can withstand high water pressure and are less likely to burst or develop leaks. This longevity translates into fewer maintenance and repair issues for homeowners.

- Cost-effective

Both initial installation expenses and long-term maintenance should be considered when considering plumbing materials to use. PEX pipes are often more affordable compared to traditional materials like copper.

The ease of installation and the reduction in fittings also contribute to cost savings. The durability and resistance to corrosion of PEX pipes minimize the need for frequent repairs or replacements, further reducing long-term costs. [6]

Polybutylene pipes were initially attractive due to their low-cost installation.

However, the issues related to premature failure and subsequent remediation have resulted in significant expenses for affected homeowners. The potential for costly repairs or replacements due to failures in PB pipes makes them more costly than PEX.

- Safety Assurance

Water quality is a critical consideration when choosing plumbing pipes. While PEX and Polybutylene pipes are generally safe, there are some concerns to be aware of. PEX pipes have been shown to have minimal chemical leaching, ensuring that the water remains pure and unaffected by the pipe material.

PEX piping has been rigorously tested and approved for safety by reputable organizations such as the National Sanitation Foundation (NSF) and the Food and Drug Administration (FDA). These certifications provide homeowners with peace of mind, knowing that their plumbing system meets stringent safety standards.

Polybutylene pipes do not have significant health risks associated with the material itself. However, failures in Polybutylene pipes, such as ruptures or leaks, can result in water damage and potentially lead to mold growth.

- Environmental Friendliness

Sustainability and environmental considerations play a crucial role in today’s plumbing systems. PEX pipes are known for their sustainability, as they are made from recyclable materials and consume less energy during manufacturing.

Thus, PEX piping is considered more environmentally friendly than Polybutylene. Due to its lightweight composition and easy installation process, PEX piping contributes to a smaller carbon footprint.

Thus, homeowners can reduce their impact on the environment with PEX [13].

Furthermore, PEX pipes contribute to water conservation, as they are less prone to leakage and can provide an efficient water flow.

While not inherently unsustainable, polybutylene pipes have faced environmental challenges due to premature failures. The potential for leaks and water loss associated with aging Polybutylene pipes can also impact overall water conservation efforts.

Related: PEX A vs PEX B

Conclusion

Although once considered an innovative solution for plumbing, polybutylene pipes have now become associated with significant risks. As a result, many homeowners opt to replace PB pipes with PEX piping, seeking enhanced safety, durability, flexibility, and corrosion resistance.

By replacing their pipes, homeowners can enjoy a more efficient plumbing system and greater peace of mind.

For homeowners in need of PB replacement, it is important to consult plumbing professionals to guide you in selecting the best piping option and ensuring a safe and efficient installation. Also, stay updated with industry developments which will help you make an informed choice for your plumbing needs.

Read Also: How to Identify Polybutylene Pipes

Michael Davis is a heating & plumbing expert who currently works as independent contractor in SC. He also writes for Plumbertip.

For almost 10 years he worked on various plumbing tasks across South Carolina.