Do you know what is the difference between PEX A vs PEX B?

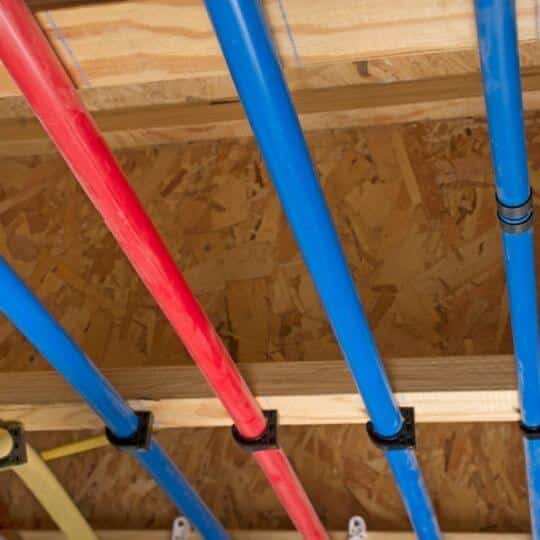

The plumbing industry experienced a revolution with the introduction of PEX piping. The pipe is known for its remarkable versatility, durability, and ease of installation.

Among the three available PEX options available, PEX A and PEX B are the primary types dominating the market.

The choice between these two can significantly impact the performance and longevity of your plumbing system. Understanding the key differences between PEX A and PEX B will enable you to make a wise choice.

The differences, distinct qualities, installation techniques, durability, pricing, purposes, and other significant considerations for PEX A and PEX B are addressed below.

PEX A vs PEX B

PEX is a plastic material pipe manufactured from cross-linked polyethylene. It possesses several advantageous characteristics, making it an appealing choice for plumbing installations. PEX is very flexible. This feature allows for maneuverability thereby eliminating the use of additional fittings.

It is exceptionally strong, corrosion-resistant, and can withstand extreme temperatures and pressures [1].

Furthermore, PEX offers advantages over traditional plumbing materials like copper and PVC, such as cost-effectiveness and ease of installation.

What Is PEX A?

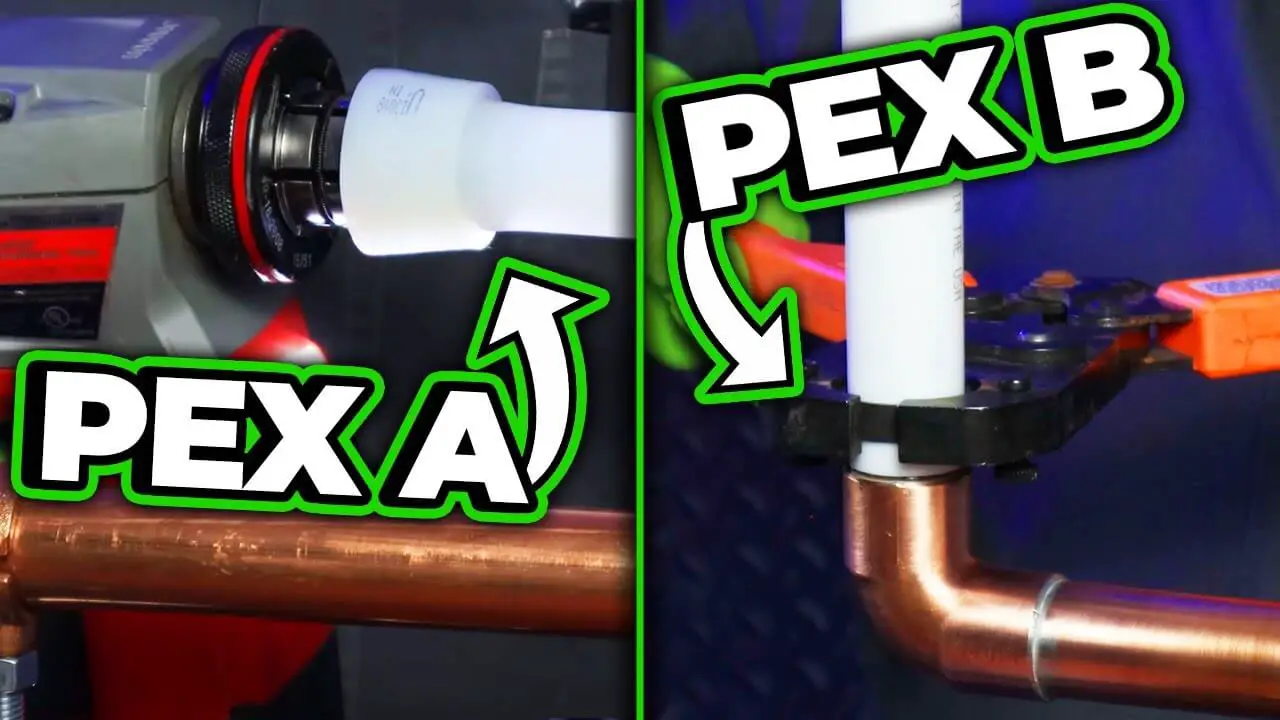

PEX A, or cross-linked polyethylene type A, is a high-density polyethylene (HDPE) pipe that undergoes the Engel method, a unique cross-linking process [2].

This process adds peroxides to the HDPE material, enhancing bonding and allowing for higher cross-linking.

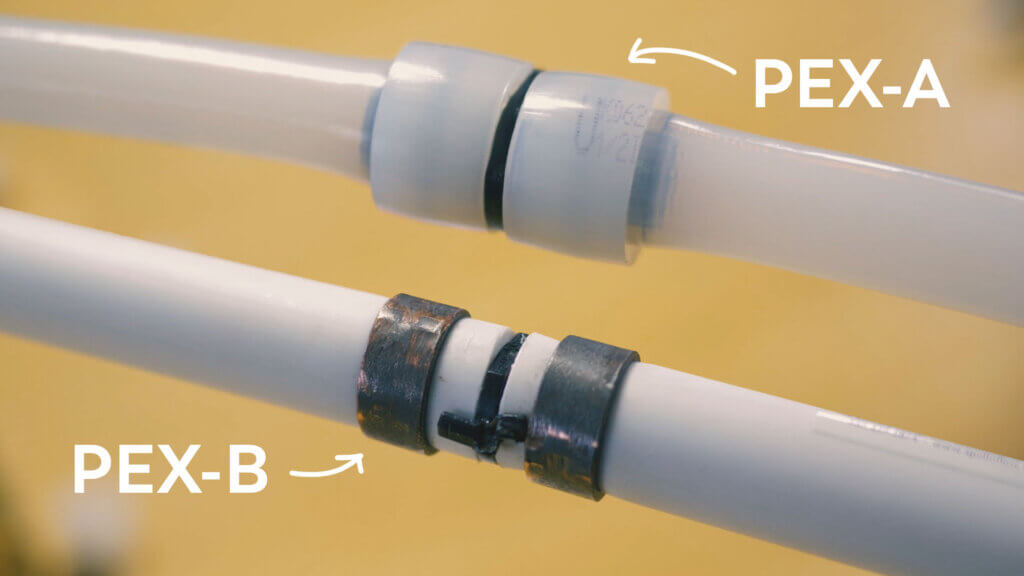

PEX A is highly flexible, suitable for cold expansion, and easy installation. It is resistant to kinking and requires expansion-style fittings for secure, leak-free connections.

PEX-A is ideal for complex plumbing layouts, offering superior elongation. It withstands temperature fluctuations without bursting. It can be easily repaired using the expansion method, allowing for seamless fittings without additional couplings.

What Is PEX B?

PEX B, or cross-linked polyethylene type B, is a popular type of PEX pipe formed through the Silane process [3].

The process involves extruding HDPE material and exposure to steam. This process simplifies the installation process and speeds it up, making it more straightforward.

PEX B pipes ensure high-quality and reliable performance by meeting the same ASTM standards as PEX A pipes. During the joining process, PEX B is unaffected by hot or cold temperatures. This means the installation can be carried out reliably regardless of temperature.

However, the recommended course of action is to avoid expansion due to its inflexibility. This is because the fittings used are smaller, which leads to tighter joints and increased resistance to water flow.

PEX A vs PEX B – Analysis and Decision Making Factors

- Installation and Flexibility

PEX A’s installation process is known for its simplicity and efficiency. Its exceptional flexibility allows it to bend and navigate tight spaces without fittings. The expansion method enables effortless fitting connections by using an expansion tool to enlarge the PEX A pipe.

This method eliminates the risk of leaks associated with fittings. Consequently, it is ideal for concealed or hard-to-reach areas. Compared to PEX A, PEX B is harder, making maneuvering in narrow spaces more challenging.

The installation process usually includes using fittings and crimp rings, thereby adding extra steps to the installation. While PEX B may be less flexible, it is still suitable for straight runs and installations that do not require excessive bending or turning .

- Durability and Longevity

PEX-A demonstrates excellent durability, especially in extreme weather conditions. Its ability to expand and contract without damage makes it highly resistant to freeze and burst damage. PEX A’s inherent flexibility also contributes to its resistance to corrosion, reducing the risk of pipe deterioration over time.

With proper installation and maintenance, PEX A systems can provide reliable performance for many years [4].

PEX-B, with its rigid structure, offers robust resistance to chemicals and impact. It is less prone to stress cracking, making it suitable for applications where chemical exposure is a concern.

However, PEX B may be more susceptible to brittleness over time, particularly when exposed to UV radiation. This limitation requires careful consideration when using PEX-B in outdoor installations or areas exposed to sunlight.

- Cost and Accessibility

PEX-A generally incurs a higher initial cost than PEX B due to its superior properties and manufacturing process. However, it provides long-term cost benefits by lowering maintenance and repair expenditures. The expansion method used in PEX A installations eliminates the need for additional fittings and couplings. This minimizes the potential for leaks and associated repairs.

PEX B, on the other hand, is more cost-effective regarding material expenses. Its manufacturing process increases production efficiency, resulting in a lower price point [5].

However, the initial cost advantage of PEX B should be balanced with the potential for higher maintenance and repair costs due to the use of fittings and couplings.

Accessibility may also influence the choice between PEX A and PEX B. While both types are widely available, the specific brand, size, and fittings required for your project may vary. Before making a decision, ensure that the chosen PEX type and its related components are available in your local market.

- Applications and Suitability

PEX A is strong in many applications, including radiant heating systems, residential plumbing, and commercial installations. Its flexibility allows easy installation around obstacles, making it suitable for complex layouts.

The expansion method also facilitates quick repairs and modifications, ensuring minimal disruption to the plumbing system.

PEX B, with its stiffer structure, is better suited for applications that require straight runs and minimal bending [6].

It is commonly used in outdoor plumbing, exposed installations, and specific industrial settings where chemical resistance is crucial.

PEX B can withstand high pressure and temperature conditions, making it a reliable choice for various applications. While PEX A may be the preferred choice for most applications, PEX B can be a viable alternative depending on the installation demands and expected usage.

- Codes and Standards

Specific codes and standards regulate PEX A and PEX B usage to ensure the safety and performance of plumbing systems. Local building codes often dictate the requirements for PEX installations, including pipe sizing, fitting specifications, and testing procedures.

Be sure to consult your region’s codes and standards authority before selecting and installing PEX systems. As well, certain regions may have exclusive restrictions or criteria for the use of PEX A or PEX B. Understanding these regional variations will help to ensure compliance and optimal system performance.

- Environmental Considerations

Environmental sustainability has recently become a significant concern in the construction and plumbing industries. When assessing PEX A and PEX B, be sure to consider their environmental impact. PEX, in general, is considered a more environmentally friendly alternative to traditional plumbing materials like copper or PVC [7].

It requires fewer resources during manufacturing and has a lower carbon footprint. Beyond that both are recyclable materials, adding to their sustainability credentials.

However, it’s worth noting that PEX B, being more rigid and less flexible, may require additional fittings and couplings during installation.

These additional components can increase material waste and contribute to a larger carbon footprint compared to the expansion method used in PEX A installations. Therefore, if environmental sustainability is a priority, PEX A may be the preferred choice due to its minimal use of additional fittings.

- Warranty and Support

Warranty and support offered by manufacturers are important factors when comparing PEX A and PEX B. Different brands may have varying warranty terms and customer support, which can influence your decision-making process.

Conducting thorough research and comparing diverse manufacturers’ warranty coverage, customer service, and reputation is advisable before selecting a specific PEX type for your project.

- Emerging Technologies and Future Developments

The plumbing industry continues to evolve, and new technologies and advancements in PEX systems are continually being developed. Stay updated on the latest trends and innovations, such as improved formulations for PEX B or new installation methods for PEX A, as these developments may influence your decision.

Additionally, consider exploring emerging trends such as smart plumbing systems, energy-efficient solutions, and water conservation initiatives.

These factors may impact your overall plumbing system design and the choice between PEX A and PEX B.

- Customer Experiences and Industry Recommendations

Real-world experiences and testimonials from PEX A or PEX B experts give significant facts about the operation and reliability of these systems. Plumbing experts and manufacturers often offer recommendations based on their extensive experience and technical knowledge.

Thus, consider seeking advice from professionals in the plumbing industry to gain a comprehensive understanding of the advantages and drawbacks of each PEX type. This will give valuable insight into the best strategies for installation, maintenance, and potential compatibility problems with pre-existing plumbing systems.

Other Considerations

A few additional factors must be considered when choosing between PEX A vs PEX B. Both PEX A and PEX B have maximum temperature and pressure ratings. It’s imperative to know that pressure ratings decrease at higher water temperatures.

You should also consider freeze tolerance. PEX A has superior freeze tolerance compared to PEX B. Its expansive nature allows it to withstand pressures up to 500 psi without bursting. PEX B, being more rigid, may not fare as well in extremely cold conditions.

Consequently, climate and weather conditions should be considered when choosing the suitable PEX type and implementing measures to protect the pipe against freezing temperatures. Understanding these limitations is essential for selecting the appropriate type of PEX pipe for your specific application.

Related: Best PEX Crimp Tool For Tight Spaces

Conclusion

PEX-A and PEX-B are popular cross-linked polyethylene pipes offering numerous benefits over traditional plumbing materials. PEX-A provides exceptional flexibility, easy installation with expansion fittings, and excellent resistance to freeze damage.

PEX-B is slightly stiffer but offers durability, affordability, and widespread acceptance in plumbing. Conducting thorough research and weighing the advantages and disadvantages of each type will help you select the most suitable PEX system for your plumbing needs.

Always consult with professionals and reputable suppliers to ensure you make the most informed decision. The battle between PEX A vs PEX B offers a wealth of choices, ensuring that you can find the perfect solution for your plumbing system’s longevity, efficiency, and reliability.

Related: Why Is PEX Plumbing Bad

Michael Davis is a heating & plumbing expert who currently works as independent contractor in SC. He also writes for Plumbertip.

For almost 10 years he worked on various plumbing tasks across South Carolina.