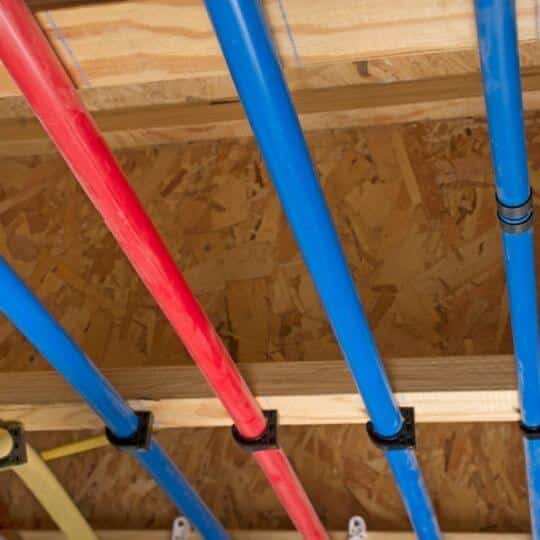

Even if you are fairly new at DIY projects, you already know what PVC pipes are. However, were you aware that there are numerous different types of PVC pipes?

While all of them might look the same to a novice, plastic pipes come in various forms.

Each type has a preferable purpose and is better than others at achieving a certain goal. In the further text, we’ll name all the different types of PVC pipes and explain what to use them for.

What Are All the Different Types of PVC Pipes?

Polyvinyl Chloride pipes – also known as PVC pipes – are the most common pipes for plumbing today. They are durable and able to withstand the water pressure without tearing or cracking.

Fixing PVC leak is much easier than fixing coppxer leaks, which is another reason plumbers prefer them.

There are a few differences between copper and plastic pipes.

They are sustainable and recyclable, making them more earth-friendly than pipes people make from most other materials.

As plumbers name all of them ‘plastic pipes’, most people don’t even know that different types of PVC pipes exist.

Still, even they come in various shapes and sizes, and people use multiple methods to make them.

There are four types of PVC pipes:

- Unplasticized PVC (PVC-U)

- Chlorinated PVC (C-PVC)

- Molecular oriented PVC (PVC-O)

- High Impact PVC (PVC-Hi)

While all types share many features, including durability, safety, recyclability, and sustainability, they are different in various ways.

Each type has its own advantages, and each is better for a certain application.

Unplasticized PVC

PVC-U is a pipe created without a plasticizer. According to ChemistryViews, a plasticizer is a substance, typically phthalates, manufacturers add to the material to make it flexible and softer.

In other words, plasticizer increases plasticity, decreases viscosity, or decreases friction. A PVC-U pipe is also commonly known as rigid PVC.

Unplasticized PVC is usually used for:

- Pipes and fittings

- Drinking water, waste, and soil transportation.

- Sewage

- Industrial drainage

- Industrial applications

There are many benefits to using fittings and pipes made from unplasticized PVC. First and foremost, they are lightweight, affordable, and easy to handle.

This makes them a perfect choice for drinking water transportation. They have a high mechanical performance, high chemical resistance, and resistance to UV exposure.

This makes them rather durable. Another great side of unplasticized PVC is that it is fully recyclable. Because of this, they are considered the most environmentally-friendly pipes for sewage.

Chlorinated PVC

Chlorinated PVC, or C-PVC pipes, are pipes with higher chlorine content. They are made by chlorination of PVC resin.

Manufacturers introduced them to the water distribution systems in the 1960s, but their manufacturing process did change a bit.

There are many additives in chlorinated PVC, such as pigments, lubricants, stabilizers, and impact modifiers.

C-PVC pipes have many advantages to unplasticized PVC pipes. Due to this, they are a popular choice for:

- Pipes and fittings

- Drinking water transportation

- Carrying water with a wider range of temperatures

- Handling of industrial liquids

Just like unplasticized PVC pipes, chlorinated PVC pipes are highly resistant to corrosion and safe to use for drinking water. Also, both are durable due to their great impact resistance.

The biggest difference is that chlorinated PVC pipes are resistant to a wide range of temperatures. This makes them a great choice for sewer systems in both residential areas and commercial construction.

They are also much more flexible compared to U-PVC, as they contain plasticizers. While C-PVC is more ductile compared to PVC-U, both are entirely recyclable.

Due to these features, they are praised by environmentalists all over the globe.

Does the chlorination of PVC affect the quality of drinking water?

While chlorine can affect the odor and taste of water, it won’t ruin its quality. On the contrary, chlorinating water is a common way of providing safe tap water.

Because of this, chlorine from C-PVC pipes won’t, in any way, ruin the safety of drinking water. Simultaneously, chlorine from the drinking water won’t damage or change the properties of a PVC pipe.

Because of this, using chlorinated PVC pipes is perfectly safe for drinking water transportation. [1]

Molecularly Oriented PVC

One of the many different types of PVC pipes is PVC-O or molecularly oriented PVC.

Manufactures produce molecularly oriented PVC by turning the amorphous PVC-U structure into a much more layered form. This makes it an enhanced version of unplasticized PVC.

People usually use Molecularly oriented PVC pipes for:

- Pipes and fittings where strong pressure is expected

- Sewer systems in unstable grounds

- Irrigation pipes

- Sewer pumping mains

Compared to U-PVC, molecularly oriented PVC pipes have a higher resistance to corrosion, recyclability, water quality preservation, and cost-efficiency.

If you happen to reside in an area where pipes are commonly exposed to pressure, you might want to consider using them.

They provide an excellent balance between stiffness, flexibility, and strength.

Molecularly Oriented PVC pipes have a great hydraulic capacity, resistance to cracks, and ductility. This makes them very long-lasting and resistant to fatigue and impact.

Simultaneously, they are 100% recyclable, which is very important to numerous homeowners and professionals.

High Impact PVC

High impact PVC, or PVC-Hi, is the newest type of PVC pipes. Manufacturers make them by inserting various chemicals into PVC-U, increasing their resistance to impact.

While standard PVC has many advantages, it had limited usages as it wasn’t stable enough. To solve this problem, professionals alloyed PVC with polycarbonate.

This formed an alloy composition with high dimensional stability, especially when exposed to heat or pressure.

In the end, this created a strong thermoplastic resin composition with high-impact strength and thermal distortion resistance.

This composition usually includes polycarbonate and an alloy of a vinyl chloride resin. Other material combination consists of ethylene-vinyl acetate and butadiene-modified acrylic. Both variations proved to be very rigid.

PVC-Hi is used on occasions when standard PVC wouldn’t handle the pressure or the extreme temperatures.

Because of this, it’s commonly used for industrial liquids or in commercial sewage systems. It’s also a decent choice if you’re planning on connecting 2 pipes, as it won’t get damaged during the cutting.

What Are Schedule 40 and Schedule 80 PVC Pipes?

Another way you can sort different types of PVC pipes is on schedule 40 and schedule 80. Unlike previous types, these two can be differentiated just by looking at them.

Schedule 40 PVC pipes are typically white, while schedule 80 are dark grey. However, there is more to it. We’ll explain below.

Difference in strength

The main and most important difference between these two pipe types is their thickness. Schedule 80 pipes are stronger and thicker, as they are designed to withstand higher pressures.

It is used when you need to transport water or liquid under higher pressure. At the same time, it’s more commonly used in situations where people expect a lot of external pressure.

Despite this, schedule 40 PVC pipes are the ones you commonly see in properties. The white line that provides drainage in buildings, that’s the schedule 40 PVC pipe.

You can easily find it in most hardware stores. These pipes are used for:

- Drinking water delivery

- Drainage

- Irrigation

- Coldwater systems

These PVC pipes are rigid, strong, and they can handle pressure very well. Depending on their material, they can deal with various temperatures, hot and cold.

However, if you need to set up a pipe where you expect high-pressure levels, you should use a schedule 80.

Typically, all different types of PVC pipes and fittings have a maximum pressure level written on their packaging or bodies.

While the exact amount of pressure they can handle depends on the pipe’s size, schedule 80 is always more durable.

Say you have a schedule 40 and schedule 80 pipes of the same size. Schedule 80 will handle a significantly larger amount of pressure than schedule 40 one.

The difference in inside diameter

Imagine if both schedule 40 and schedule 80 PVC pipes were of the same color. It would be impossible to tell the difference just by looking at them.

This is because both types have the same outside diameter. However, if you were cutting PVC pipe, you would notice another difference. That is the inside diameter of the pipe.

While they seem equally thick, schedule 40 pipes have a significantly larger inside diameter than schedule 80 ones. This is because schedule 80 pipes have thicker walls.

Thick walls make them stronger and more rigid compared to schedule 40 ones. This does have a downside. The water flow is much more restricted in a schedule 80 pipe compared to a schedule 40 one.

Difference in weight

As we’ve already established that schedule 80 pipes are thicker than schedule 40 pipes, the next difference is logical. Schedule 80 pipes are much heavier than schedule 40 pipes.

This can limit your options on where you want to install it. At the same time, schedule 80 pipes can be more expensive to ship or deliver to your property.

These are additional expenses that you need to consider when buying PVC pipes.

Difference in price

Schedule 40 price is always less expensive than a schedule 80 pipe of the same outside diameter. This is because it takes more material to make a schedule 80 PVC.

More used materials will always mean a higher price.

Are there any other schedules of PVC pipes?

While schedule 40 and schedule 80 pipes are more common, there is also a schedule 20 and schedule 120 PVC pipe. Schedule 20 pipes are thinner than schedule 40 pipes.

Because of that, they are rarely used for plumbing. The only option where you can use them is if there isn’t any traffic crossing over the area.

They are much more fragile, and they can crack easily.

On the other hand, schedule 120 PVC pipes are the most robust of all. People commonly use them in construction areas when there is a lot of expected pressure.

You can’t find them in most stores, so professionals rarely use them.

Both of these pipes are in different shades of grey compared to schedule 80 ones. This makes them easy to differentiate.

Read Also: How Long Copper Pipes Last

What Type of PVC Pipe Should You Use?

Now that you know there are different types of PVC pipes, you probably wonder which one you should use. This is entirely up to your project and the situation your property is in. Take note that we don’t recommend using polybutylene pipes.

If you live in an area with a lot of traffic, we would recommend using a schedule 80 PVC-Hi pipe. On the other hand, if you live in a neighborhood without a lot of pressure, such thick pipes aren’t necessary.

It would be enough if you’d used a schedule 40 PVC-U pipe for your sewage system.

Of course, you should discuss all of this with a licensed professional in your area. This is the best way to determine which type of PVC pipe works best for you and your property.

However, we hope this article provided you with insight into different types of PVC pipes.

Read Next: Should I Buy House With Polybutylene Pipes

Michael Davis is a heating & plumbing expert who currently works as independent contractor in SC. He also writes for Plumbertip.

For almost 10 years he worked on various plumbing tasks across South Carolina.