If you are a professional who works with plumbing and sewerage installations, you have probably heard or already worked with different types of PEX [1] pipes, whether they are versions A, B, or C. This type of pipe is flexible and provides a high level of resistance to temperature extremes. If you are not a professional, but you are researching the topic in the process of planning your household, this text can serve you and offer an answer to the question: can PEX be used for air lines?

The conductivity of these pipes when it comes to water is at an enviable level compared to PVC pipes or copper pipes, but there are still more details that you need to think about before you go shopping.

Ventilation systems made of metal raw materials are massive, heavy, complicated to maintain, and above all expensive. Every possible breakdown and service, they bring with them many demanding operations, and the parts cost a lot.

The problem might be if the plumber is equipped with all the parts, or he has to order them and wait until they arrive.

Of all the metals, stainless steel and copper pipes, as well as their joints, are the most expensive. In addition, they are most commonly used in large commercial and industrial plants that require durability and long-term use.

Can PEX Be Used for Compressed Air Lines?

In the design of your household, one of the advantages is that through the layout of the rooms you can draw the central ventilation and thus provide fresh air in all rooms. The question is what materials will you use in the installations of your ventilation system and how much do they cost?

PEX pipes are more resistant to temperature changes than other materials used.

Also, we remind you of the composition of PEX pipes, so that they are flexible and can be stretched, bent at low temperatures up to 40F, but also connected by a heat gun.

These materials do not require a lot of compounds, which is also one of the advantages. These all make a big cost advantage, as there are no joints, elbows, and extra work when working with PEX pipes.

How to Use PEX for Air Lines?

The great advantage of working with PEX pipes is that cross-linking polyethylene [2] was created to ensure the stability of materials when working at extreme temperatures, whether high or low.

This results in improved material and greater resistance of the pipe to cracking, as well as durability if cracks grow.

Some manufacturers recommend the use of PEX pipes for air lines, due to their resistance, provided that:

- Keep the pipes protected from the sun and UV radiation

- Adequately connect the pipes in certain places and tighten the joints

- Since the pipes are flexible and elastic in their composition, fewer joints will be made in creating air lines.

You have to take into account that it is very possible that the pipes will let very small amounts of air through the joints, which can reduce the efficiency and quality of your air lines, but this is a risk you take before starting the ventilation system when working with PEX pipes.

Can PEX be Used for Air Lines?

If we talk about the resistance of PEX pipes to low and high temperatures, the measures that need to be taken to protect the entire water supply and sewerage system in the household, it is certain that PEX pipes can be used for air lines.

Also, if you stay a little longer on our site you can find many informative, useful things that can offer you answers to the dilemmas you have before or during the installation of water supply pipes in your household, installation and maintenance of sewage systems.

The novelty is certainly the use of PEX pipes for air lines, which is certainly a topic that deserves our attention and finding answers that solve many dilemmas and suggest solutions for your household.

Can PEX be Used For Air Lines?

We recommend for smaller systems and households to use PEX pipes when making air lines. This system can be easy to install and maintain, and at the same time, it is flexible since the joints connect themselves. Experience has shown that it is easiest to work with when it comes to modifications or reinstallation.

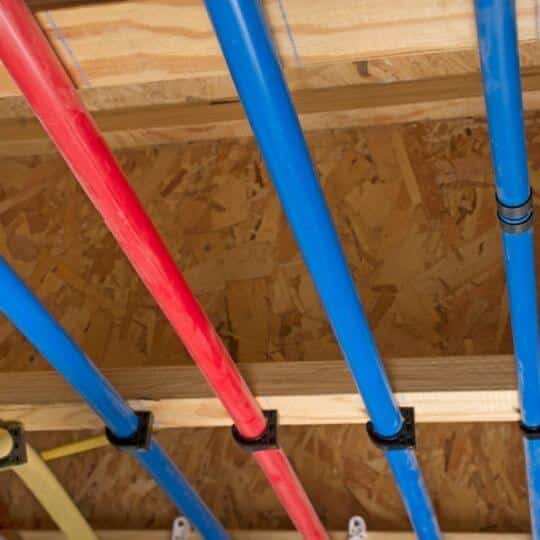

Due to its elasticity, very often PEX pipes can be placed where it seems significantly more difficult to install solid, rigid pipes such as finished walls and ceilings of buildings.

You have to be prepared to work even with this type of pipe, since your requirements are specific in making air lines. You can’t find PEX joints in stores such as “Home Center” or Hardware stores, but it’s best to look for them in advance and install them before setting up.

It would not be bad to order a few more joints, in case they get damaged during installation or do not do the job as expected. In order not to wait too long for the delivery of the next round of joints, make sure you are on time. According to available information [4], several companies have and supply PEX pipes, as well as fittings.

Our Recommendation

Before you start installing the system, install condensation filters (moisture) in your air line system for several reasons:

If you plan to use a condensed air system for finishing, likely, you will not achieve the desired effect as long as there is water in it.

- Pneumatic tools work best and longest if clean, dry air is used.

- Also, humid air can help rust and corrosion occur in the compressor and all metal components if they are found in the pipes of your system. That is why it is important to dry the compressor, as well as all filters regularly.

For your airline made from PEX pipes to last longer and do its job as well as possible, it should not be difficult for you to follow these few tips. They can help keep PEX tubes used long and successfully in your air lines system.

Voice of Plumbing Professional

Different experiences of professionals and those who install plumbing, sewerage, and ventilation systems themselves provide different information. Someone you trust may have a bad experience and convey to you negative impressions about the use of certain materials or raw materials from certain manufacturers.

However, we have tried to convey to you as objective information as possible when it comes to the dilemma of “can PEX be used for air lines”. The composition of PEX pipes contributes to their elasticity, which makes it possible to thread them into your system without many joints.

On the other hand, PEX pipes are very resistant to extreme temperatures, whether high or low and are therefore a frequent choice of professionals. Their elasticity is a guarantee that they expand and shrink quickly, which prevents them from hardening and cracking at low temperatures.

To be honest, PEX pipes do not tolerate sunlight or UV rays, which is why you should avoid outdoor installation and exposure to these lights.

Their low price is one of the main motives why can PEX be used for air lines.

The most important thing is to follow the advice of more experienced, use the information you read about the use of PEX pipes for compressed air lines and prevent any possible problems that may occur, which leads to additional costs and new problems that repair or installation of a new system can bring.

Michael Davis is a heating & plumbing expert who currently works as independent contractor in SC. He also writes for Plumbertip.

For almost 10 years he worked on various plumbing tasks across South Carolina.