PEX plastic fittings vs brass is an age-old debate amongst consumers and plumbing experts. Some swear that brass is unsurpassed in its qualities, while others consider plastic PEX fittings similar or even superior to brass.

As a consumer, the fittings you choose to use ultimately depend on the type of installation, budget, and personal preference. This article presents both sides of the PEX plastic fittings vs. brass debate. It is intended to help you make an informed purchase decision.

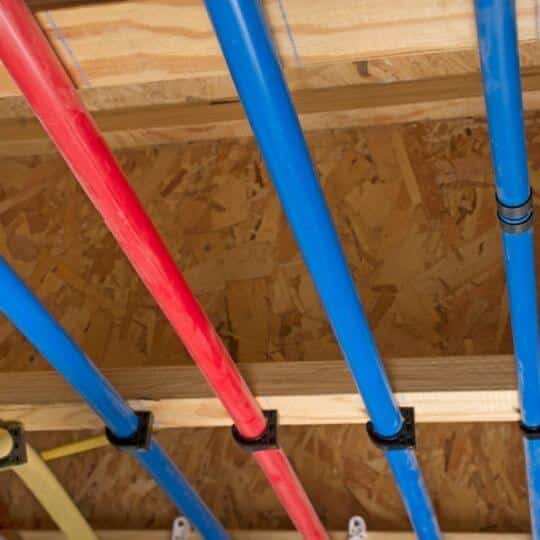

PEX Piping Systems

Cross-linked Polyethylene (PEX) is a synthetic plastic product manufactured from high or medium-density polyethylene. Polyethylene is altered to enhance its properties like stability, long-term strength, and heat resistance [1].

The resulting product is suitable for cold and hot water distribution systems as well as service lines.

It is also used in hydronic heating and residential firefighting systems. PEX tubing fittings are popular in plumbing systems because they are superior to ordinary plastic. Their appeal also stems from the fact that they are less expensive compared to copper and brass fittings. The products are also used in radiation floor heating systems.

PEX tubes range in sizes from a quarter-of-an-inch to three-inch nominal diameter. Different types and sizes of fittings are used to connect PEX pipes. The most common ones are plastic, brass, and copper PEX pipe fittings.

PEX Plastic Fittings vs Brass

There are numerous types of products and tools to use when working with PEX plastic fittings vs. brass for piping systems. Before selecting plumbing fittings to use with PEX pipes, you should consider their quality, cost, and ease of installation.

It is always recommended that you survey the market first to avoid making costly mistakes. Plumbers and homeowners who use the wrong types of fittings for PEX piping systems end up regretting. They are forced to incur additional repair costs that may not be covered by a warranty.

Brass fittings are applied in pipe systems that convey water, flammable gases, chemicals slurries, and other substances used in plumbing. Brass pipe fittings come in a diversity of thread sizes and shapes. This means that they can be adapted, connected, or controlled to suit any piping system.

Apart from plumbing, brass fittings are commonly applied in the automotive industry. Their application in this field entails the manufacture of fuel line valves, air brakes, and hose ends.

They are also found in ballcock adapters, compression fittings, and refrigerator cooler fittings.

Although some consider PEX plastic fittings as inferior to and less durable than brass, this is not quite the case. Plastic fittings for PEX piping are better and more effective than their brass counterparts in some circumstances.

Brass and plastic fittings are applied in different cases as a result of their different properties.

Their advantages and disadvantages make them ideal for use in diverse circumstances. For instance, plastic fittings are considered suitable for installations that convey acidic or poor-quality water. Acidic water tends to corrode brass fittings easily and could lead to wearing away and failure of the entire system. Plastic fittings, however, have no such problem.

In contrast, installations of systems that handle extreme temperature changes are not ideal for plastic fittings. Because brass can withstand higher temperatures as compared to plastic fittings, they are recommended for such installations. [2]

Examples of this include pipes and fittings for boiler and central home heating systems. The various advantages and demerits of PEX plastic fittings vs. brass are outlined below.

Advantages of Brass Fittings

- They are more durable than plastic if installed correctly.

- They have the capacity to withstand higher temperatures.

- They have greater malleability.

- They exist in diverse shapes and sizes.

- They are less susceptible to corrosion compared to copper and other metals.

Disadvantages of Brass Fittings

- They cannot handle acidic or poor-quality water.

- They are prone to failure under extreme temperatures.

- They are more expensive to acquire and install.

- They corrode quickly when exposed to acidic environments.

- Because they are better conductors of heat than plastic fittings, their use may result in loss of heat along the conveyance line.

Advantages of Plastic Fittings

- They are lighter compared to brass fittings.

- They are less expensive.

- They are less susceptible to chemical attacks in acidic environments and poor water quality.

- They have better elastic properties compared to brass fittings.

- Their smooth internal surfaces reduce friction and save energy in the conveyance of fluids.

- They are less likely to leak due to fewer joints.

Disadvantages of Plastic Fittings

- The installation process is more demanding than brass fittings.

- They do not handle high temperatures well and may soften and fail.

- Their strength reduces at high temperatures.

- They are non-biodegradable, hence contributing to environmental pollution.

- They are less resistant to shock and may crack or deform easily upon impact.

PEX Plastic Fittings Problems

While defective manufacturing problems are slowly becoming a thing of the past, other issues have arisen to replace them. Proper installation and care of PEX plastic systems and fittings are necessary to ensure they operate optimally.

Many consumers wonder whether plastic PEX fittings are good or bad. This, however, is influenced by several factors. The first reason why homeowners experience PEX plastic fittings problems is the failure of the pressure test.

While PEX fittings and pipes can withstand much pressure, failure to adhere to pressure testing specifications can cause problems. Too much stress can result in the bursting of fittings and pipes. This might require the removal of entire fixtures, floors, and walls and expensive repairs.

The second problem has to do with frozen pipes. In temperate climates, where temperatures reach sub-zero levels, water in the pipes can freeze, causing the pipes to burst. Additionally, when the water in the PEX plastic pipes and fittings is over-chlorinated, it causes problems. It tends to be too aggressive for the system, particularly at high temperatures. [3]

The excess chlorine can result from water treatment or sanitation of the piping system with excess chlorine concentrations. This dramatically reduces the lifespan of the PEX plastic piping and fittings.

PEX Brass Fittings Problems

PEX plastic is a recent material to be used in the plumbing system. It entered mainstream use in the 1980s and has been growing in popularity ever since. Although PEX piping itself is reliable and flexible, trying to connect such systems to those of other materials presents challenges.

Brass fittings are commonly used in such connections. Pipe connections need to work correctly if the entire piping system is to be effective. Failure of even a single fitting can cause leaks or significant loss of flow.

Any pipe fitting that leaks, degrades, or corrodes prematurely is regarded as defective in the plumbing world. Common problems encountered with PEX brass fittings include leaking due to improper connections and corrosion leading to poor-quality water.

Poor quality brass resulting from high concentrations of zinc corrodes quickly and causes leaks in brass fittings. When the water flowing through brass fittings has high zinc content, zinc leaches out into the water.

Consequently, the fittings lose their strength in a process referred to as dezincification. [4]

This is where the fittings corrode and fail, which is problematic, especially if the piping is underground or passes through walls. By the time such leaks are discovered, they have already grown and may present serious repair challenges.

Another problem resulting from the leaching of zinc is the buildup of zinc residue inside pipes and fittings. This residue causes the flow rate within the tube to reduce, leading to high energy demands in pumping the water.

Although this is a lesser problem than the failure of the fittings, it still presents challenges to plumbers and homeowners.

Plastic PEX Fittings Temperature Rating

Plastic PEX fittings are made to withstand high temperatures. This explains why the products are suitable for both hot and cold water installations. Plastic PEX fittings temperature rating is given as 200 degrees Fahrenheit.

This, however, is the highest temperature the material can withstand before it starts losing strength and collapsing. As the temperature increases, the maximum pressure that the tubing can withstand drops significantly. For instance, plastic PEX fittings pressure rating is 160 psi at 73oF. At 180oF, the pressure rating is 100 psi, while 80 psi corresponds to 200oF (psi stands for pounds per square inch). [5]

How to Use Plastic PEX Fittings

Basic plumbing is not complicated at all. Anyone interested in a do-it-yourself project can put together a functional piping system using plastic PEX fittings and pipes. You will just need the suitable materials and tools for the job, and you are good to go.

Some of the rules and guidelines in learning how to use plastic PEX fittings are outlined below.

- Consider using the suitable materials and tools for the job. Numerous pipe materials and fittings exist, from plastic and PEX to copper and steel pipes. Although connecting pipes and fittings of different materials is possible, you should only use fittings and pipes of similar material to achieve better connections.

Plastic PEX fittings and pipes are best suited for domestic plumbing installations because they are ductile. Ductility refers to the property of an object which can easily be bent into the desired shape. This minimizes the number of bend fittings that would have been used with copper or steel pipes.

Additionally, plastic PEX pipes can be routed easily through walls and floor spaces. They are better insulators against heat loss than metal. They also have better corrosion resistance and can withstand significantly higher temperatures and pressures.

- PEX plastic pipes and fittings should not be used outdoors or where they can be exposed to fluorescent lighting. PEX is vulnerable to degradation from ultraviolet rays produced by sunlight and fluorescent tubes.

Where such exposure cannot be avoided, PEX tubing should be insulated to prevent disintegration. Common protection methods include painting the pipes and fittings with latex paint. They can also be covered with black plastic or vinyl steel.

In case the pipes are used indoors, consider covering your windows using a UV protective film. The film will protect from UV light.

- The heat from heat-producing tools such as blowtorches can damage plastic PEX pipes and fittings. When working with such products, care should be taken to ensure that they are not exposed to the flames.

Moreover, the piping system should be routed in such a way as to avoid exposure to extreme temperatures. Consequently, it is not advisable to install such fittings in boiler rooms or near furnaces.

- When cutting plastic PEX pipes and fittings, consider using a pipe cutting tool other than a hacksaw. Although the hacksaw can get the job done, it leaves the surface with burrs which may result in improper connections.

A proper cutting tool leaves the cut surface clean and smooth. Where the hacksaw is the only tool available, ensure that you file off the surface to get rid of burrs.

- Ensure that you match the right plastic PEX pipe with the proper fitting. The appropriate fitting in terms of material, size, and shape for the junction should be used to achieve a good connection.

Failure to do this will produce a weak joint that can cause leakage or bursting of the pipe. Similarly, a joint formed by fittings of the same material will ensure that it reacts to the surroundings the same way. Different materials expand and contract differently when exposed to changes in temperature.

PEX Plastic Fittings vs Brass – Final Word

The PEX plastic fittings vs brass discussion has presented the benefits and problems you can encounter when working with each set of fixtures. Brass fittings are superior in strength and last longer than plastic in some instances. However, plastic PEX fittings are cheaper, easier to install, and are suitable in situations where the water transported is acidic.

While brass was well-liked in the past, PEX plastic is becoming increasingly popular due to the benefits outlined above. Whichever system of tubing and fittings you choose, ensure that proper care is taken during installation. This includes adhering to industry specifications to ensure that the system serves you as intended.

Michael Davis is a heating & plumbing expert who currently works as independent contractor in SC. He also writes for Plumbertip.

For almost 10 years he worked on various plumbing tasks across South Carolina.