Can You Use PVC Glue on CPVC? Having to run to the hardware store several times a day to buy something that you had no clue you needed is among the most unsatisfying aspects of home enhancement projects. You rush to the nearby store to get a particular plumbing component only for the plumber to send you back for something else entirely.

For instance, when carrying out a plumbing job and you realize that you are using CPVC pipe but the glue you have in your toolbox only works for PVC.

So can you use PVC glue on CPVC?

Well, the short answer is that you cannot. It can only work if you are using CPVC glue on PVC pipe and not the other way round. Because of the chemical composition of the two materials, PVC and CPVC exhibit different properties, which means that how they are used is also different. CPVC is stronger, more durable, and can withstand higher temperatures as compared to PVC. [1]

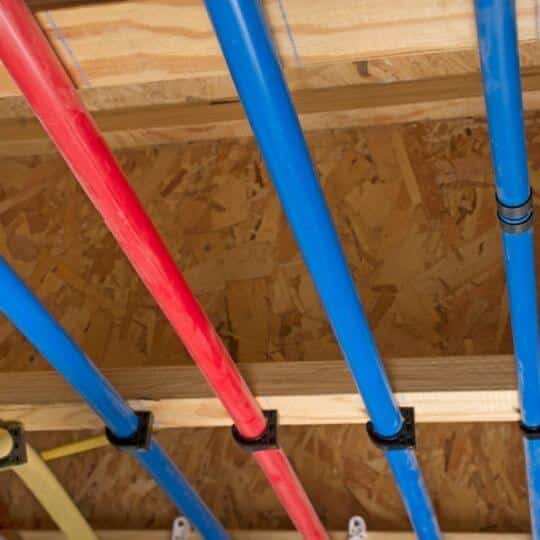

As a result, PVC pipes and fittings are commonly deployed in plumbing, drainage, and water supply systems that handle cold water. On the other hand, CPVC components are best suited for hot water systems since their tolerance to higher temperatures is greater.

Additionally, each type of material comes with its components and fittings such as glue (cement) and primer. In most cases, you cannot use PVC glue on CPVC piping because of the temperature limitation. However, CPVC glue can be deployed effectively in PVC systems without any trouble.

PVC vs CPVC

Most people know about PVC pipes. PVC stands for polyvinyl chloride. Polyvinyl chloride is a thermoplastic material that can be shaped into a variety of pipes, valves, fittings as well as other components used in conveying and handling fluids. A thermoplastic refers to a kind of plastic that is manufactured from polymer resins.

The material softens when heated and hardens when cooled. Because they do not undergo a chemical change when heated or cooled several times, thermoplastics are easier to recycle. PVC is a synthetic plastic with additional stabilizers to prevent its oxidation and degradation. It is a chemical compound made of two carbon atoms bonded together and surrounded by one chlorine atom and three hydrogen atoms.

This forms a single unit (monomer) that is then bonded to other molecules of the same structure to produce a chain (polymer). PVC is made to withstand degradation and oxidation. [2]

Therefore, the material is highly durable. It can last up to 50 years if installed properly.

Because of its durability, strength, low cost, and ease of installation, PVC has become one of the most popular plastics in use today, taking over the role of copper in piping and plumbing. In cases where PVC pipework has failed, the failure can be attributed to tree roots growing into the pipes or joints that were improperly glued.

Now that we have seen what PVC is and its applications, let us turn our attention to CPVC. CPVC can be thought of as the cousin to PVC. Essentially, PVC and CPVC use the same material in their basic structure, with only one element to tell them apart.

For CPVC, the material is changed through a reaction with free chlorine radical. The chemical composition of CPVC consists of two carbon atoms linked to two hydrogen atoms and two chlorine atoms.

This molecule (monomer) bonds with other units to form the CPVC polymer. The chlorination reaction results in an increase in its chlorine content. The resulting product is referred to as chlorinated polyvinyl chloride (CPVC), a thermoplastic that can be shaped into various products, just like PVC. CPVC has greater resistance to oxidation and degradation than PVC and also lasts longer.

Differences between PVC and CPVC

The difference in the chemical constitution of PVC and CPVC is demonstrated by several physical differences. For one, the two materials are available in different colors. PVC is mostly white whereas CPVC exists in gray, yellow, or off-white colors. This is important for telling the two products apart at a glance.

Secondly, PVC and CPVC are different with regard to the temperature they can withstand. While PVC can only handle temperatures up to 140 degrees Fahrenheit (which makes it unsuitable for use in hot water supply lines), CPVC can survive temperatures up to 200 degrees Fahrenheit.

If these temperatures are exceeded, both materials are susceptible to failure by softening, which results in pipes and joints and consequently, the entire plumbing system, failing.

Another key difference between PVC and CPVC exists in the area of sizing. Pipe manufacturers commonly gauge PVC pipes using the nominal pipe size (NPS). This system measures pipe wall thickness and gives the internal and external diameters of the pipe.

Schedule 40 and 80 are the commonest PVC pipe sizes in use today. On the other hand, CPVC uses both NPS and CTS (copper tubing size) scales. The CTS scale is used because CPVC can be adopted for the same applications as copper pipes. The two scales are not compatible, which makes it difficult to use both PVC and CPVC in the same plumbing system.

PVC vs CPVC in Applications

Technically speaking, you can connect CPVC and PVC pipes, provided you get the glue, the fittings, and the procedure right. However, most plumbers will advise against it, with a good reason.

Because CPVC and PVC have different strengths, you cannot use PVC in applications that require the properties of CPVC. And, although you can use CPVC in applications that require PVC it would be a waste of resources because CPVC is much more expensive than PVC and it will be underutilized.

In simple terms, an application of PVC and CPVC in the same system means that the system temperature should not exceed 140 degrees Fahrenheit. This proves the point that it is much more efficient to use the right material for the right job to guarantee efficiency.

PVC and CPVC Glue

Since PVC and CPVC have different chemical properties, they also vary in the solvents and primers used to connect the pipes and fit the joints together. The cement or glue used to hold the fittings together are specific to each kind of material. To understand how this works, there is a need to explain how thermoplastic glue (cement) works. PVC glue doesn’t function like normal glue.

The glue causes the surface of the pipe it has been applied to to break down, thereby chemically bonding the two pipe fittings together. This means that the kind of glue that works with PVC will not function with CPVC. CPVC is a material with higher properties of strength, tougher chemical structure, and higher melting point than PVC. Consequently, PVC glue won’t work on CPVC.

The reverse, however, can work because CPVC glue can act on PVC pipes and fittings. Joining CPVC to PVC requires the use of primer and solvent cement strong enough to act on and bond fully the CPVC pipe and the fitting. The procedure to be followed in CPVC to PVC bonding is outlined as follows.

First, you should brush about two inches of the CPVC solvent or primer both on the inside and outside of the pipe and fitting. The next step is to immediately apply a light covering of CPVC glue to the primed area inside and outside of the pipe and fitting. After this, slide the two pieces together, twist, and hold them firmly together for about 30 seconds.

Although the CPVC to PVC bond can be technically formed, the critical question to consider is why you think you should it. As pointed out earlier, CPVC and PVC have different chemical properties and, even though they share some common characteristics, they are applied in different ways.

PVC, which can only withstand temperatures up to 140 degrees Fahrenheit, is only suitable for drainage and cold water plumbing systems.

Conversely, CPVC, with its capacity to withstand temperatures up to 200 degrees Fahrenheit, is used for hot water applications. In any case, building a system that utilizes both CPVC and PVC will mean that the system requirements do not exceed the lowest property of the two components, which in this case is PVC.

This will mean that CPVC will be underutilized, even though it is more expensive to acquire and install than PVC. In short, there will be no logical justification for having such a setup. Although it can be done, it is much safer, more effective, and convenient to have separate systems depending on your need.

CPVC Glue and Primer

Can you use CPVC glue on PVC? Yes, CPVC glue will work on PVC joints and fittings. However, it is recommended that the appropriate CPVC primer for the specific application be used as well. On the contrary, PVC glue cannot be used for CPVC applications because of temperature limitations. There is a difference between glue and solvent .

Solvent welding is the chemical process in which the solvent cement or a primer is used in softening the plastic fitting’s or pipe’s surface to fuse or join them together. The process needs an interference or tight fit. The gaps between the surface of the pipe and the fitting are filled in with the solvent cement.

Conversely, PVC glue can only be used as a bonding cement and may not function with an interference fit. A primer is a substance used to pre-soften the pipe’s and fitting’s surface before the application of the solvent to ensure that maximum fusion occurs.

Can I Use Orange CPVC Cement on PVC?

Yes, you can use orange CPVC cement on PVC. Both CPVC and PVC work well for plumbing and drainage systems that deal with cold water. However, only CPVC works well with hot water systems since PVC pipes are susceptible to erosion and failure if hot water is made to flow through them. Oatey®Heavy Duty Orange CPVC glue is recommended for use for both hot and cold water plumbing systems with temperatures up to 93 degrees Celsius (200oF). [3]

It is an orange, heavy body, low VOC, and fast set glue that can be used in solvent welding of all classes and schedules of CPVC fittings and pipes up to 12 inches in diameter.

CPVC solvents can be used in fitting uPVC pipes, rigid agricultural pipes, casing pipes, SWR pipes, and uPVC column pipes. The solvent cement can withstand both cold and hot water.

When working with CPVC pipes and fittings, it is recommended that you use CPVC glue or multipurpose CPVC/PVC glue. Glue produced specifically for PVC pipes and fittings will not work well with CPVC systems because it can cause breakage and leaking.

A primer is required when working with orange CPVC cement on PVC. The primer will prepare the bonding surface before the application of glue and the subsequent bonding.

When applying the primer, make use of the appropriate tool such as a swab, dauber, or paintbrush, which is approximately half the pipe’s diameter in size. Ensure you apply the primer both to the outside of the pipe end and the inside of the fitting. For good handling strength, allow about 15 minutes while two hours of curing time are recommended at temperatures above 60oF.

Can You Use PVC Glue on CPVC – Final Word

CPVC and PVC have different chemical compositions and therefore require different primers, cement, solvents, and bonding agents to function properly. Even the industry solvents specifications for CPVC and PVC are different.

PVC solvent cement needs to adhere to the ASTM D2564 specifications while CPVC solvent cement should meet ASTM F493 specifications. This implies that solvents, primers, cement, and even the pipes and fittings for each ecosystem should not be used interchangeably, otherwise they will result in a below-par performance.

To ensure that your plumbing or drainage system serves you well, you must use the right piping materials and fittings. The two materials PVC and CPVC have unique properties and uses which can be taken advantage of if deployed properly.

Michael Davis is a heating & plumbing expert who currently works as independent contractor in SC. He also writes for Plumbertip.

For almost 10 years he worked on various plumbing tasks across South Carolina.