Anyone who uses a well for their residential water source is aware of how they operate. Air-over-water, diaphragm, and bladder are the three types of pressure tanks, each having its own set of advantages and disadvantages. For homeowners who may not have a clue, a bladder tank vs pressure tank comparison is necessary for setting their minds at ease.

Pressure tanks are utilized in various applications, but one of the most popular is to improve system efficiency. One motive for installing a pressure tank in a plumbing system, for example, is to keep the pump from constantly operating [1].

As a result, the pressure-regulating tank extends the pump’s life and minimizes maintenance and downtime, which results in cheaper running costs.

Bladder tank vs pressure tank

A bladder tank is an expansion tank that contains a bladder. A bladder expansion tank is a mechanism that absorbs the expansion force and is used for heating and cooling. It adjusts to pressure variations in compressed air by allowing water to flow in and out of the tank.

The pressure difference is caused by the expansion and contraction of water in the heater due to changes in temperature. A bladder tank that has been pre-charged with air is known as a pre-charged bladder tank. Bladder expansion tanks have the advantage of allowing you to replace the bladder as needed.

The bladder keeps the expanding water separate from the air. Consequently, water does not come into contact with the tank, thereby preventing oxygen-induced corrosion and rusting.

It also extends the pump’s life by lowering the number of pump cycles [2]. In addition, an air wall between the interior of the tank and the exterior of the bladder avoids water clogging in this arrangement.

Water vessels subjected to high pressure are referred to as diaphragm or pressure tanks. A diaphragm separates the two chambers in these tanks which contain water and air respectively. Diaphragm tanks work in the same way that bladder tanks do.

Bladder tank vs pressure tank comparison

The main distinction is that one system relies on a bladder while the other uses a diaphragm. A tank’s diaphragm cannot be replaced once damaged. It protects the system from becoming soggy and absorbing air. It safeguards water heating and cooling systems in this way.

A vinyl tank is contained within a bladder tank. When a bladder tank is depleted, it can be refilled. A diaphragm tank, on the other hand, has a rubber flat diaphragm with a butyl or vinyl tank attached to it. The diaphragm is attached to the tank’s internal section. As a result, it can’t be replaced. Both the bladder and the diaphragm tanks serve the same purpose.[3].

Pre-charged expansion tanks

A bladder or a diaphragm is used in pre-charged expansion tanks. They are used to separate the air from the water within the tank. Tanks are used as reservoirs for storing water and to reduce the daily cycle of pumps to extend their life. The bladder or diaphragm is compressed when the pump fills the tank with water. This causes a rise in pressure, which continues until the pump’s pressure switches are turned off.

A pre-charged expansion tank has been charged with air. It holds the charge and can be expanded when in use. The connection for pre-charged tanks is a single pipe. As a result, the amount of usable water increases as the tank size grows, and the number of pump cycles decreases. This arrangement helps the pump last longer operate efficiently.

Bladder tank problems

A flexible membrane (bladder) separates pressurized air and water in a bladder tank. The air in these tanks is usually pre-charged at the manufacturing. The volume occupied by air in a bladder tank increases and reduces relative to water pressure changes. Therefore, the amount of air in the tank should be measured regularly, and the tank should be replenished if the air level is too low.

Even though a bladder tank for a standard house or small commercial water system would not have a vast storage capacity, it will serve several essential purposes, including:

- It keeps the water pressure in the distribution system within a specific range.

- It reduces pump cycling, minimizing repeated starts and stops and protecting pumps from motor burnout and damage to other water system components.

- It shields the system from the effects of the water hammer [4].

Bladder tank troubleshooting guide

To check the bladder tank’s air charge if it is not working correctly:

- Turn off the pump’s electrical power.

- Open the faucet nearest to the tank to drain it.

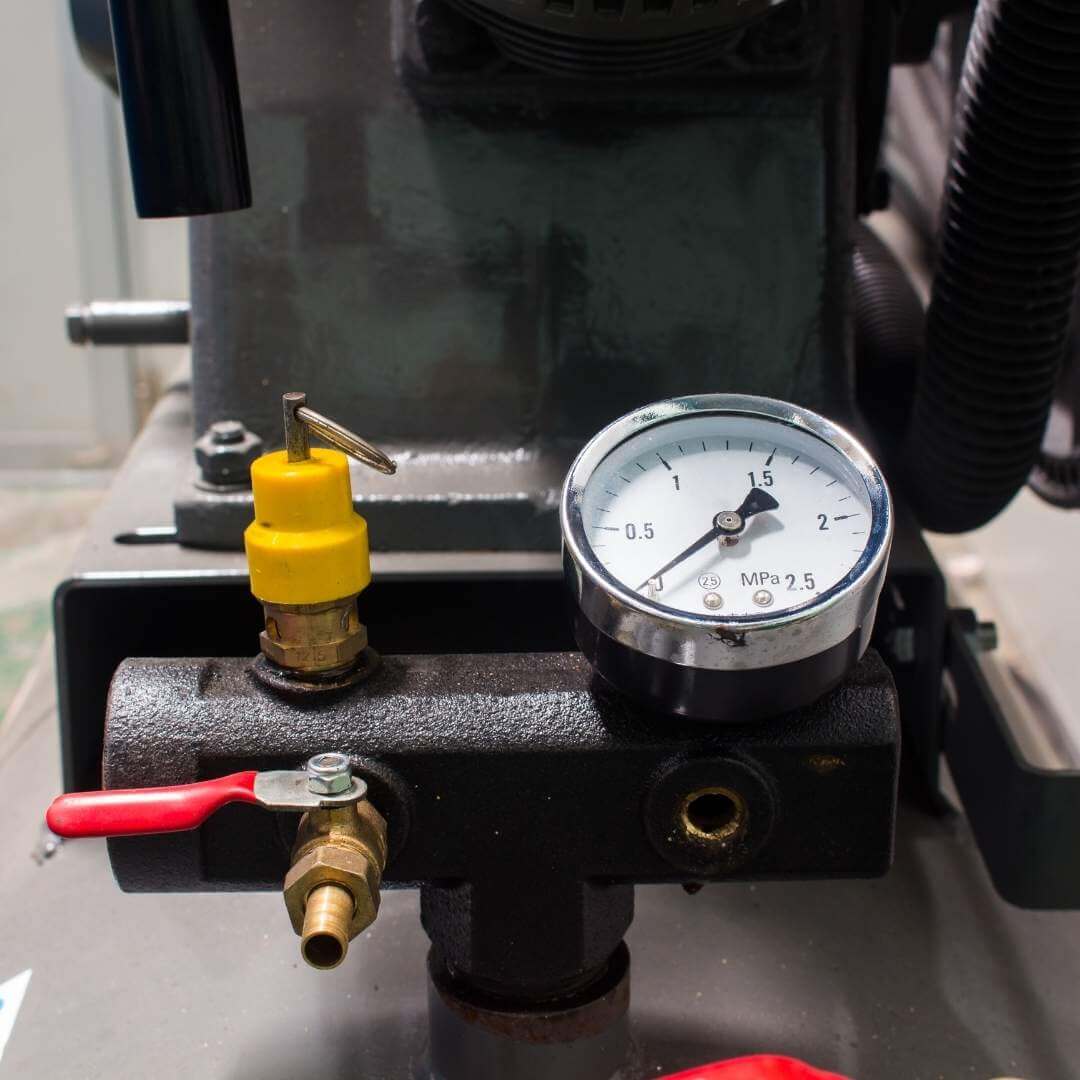

- Place an air pressure gauge on the air charging valve on the top of the tank to check the pressure.

- In case the pressure is higher than 2 psi (lower than the pump cut-in pressure), add air. When utilizing an air compressor or air pump, exercise caution.

- If the pressure is 2 psi (higher than the pump cut-in pressure), release the air (lowest pressure in the operating range).

- Check for air charging system leaks using a soap solution by dripping it on the air charging valve.

- Reset the pump, then run a normal cycle to ensure correct settings. If the tank’s pressure drops too low, the bladder inside the tank might have ruptured and needs to be replaced.

Is the bladder tank waterlogged?

You should also inspect the bladder tank to see whether it’s clogged with water. If a tank is filled with water or contains too much water to function correctly, it is considered waterlogged [5]. Clogged bladder tanks cause the following issues:

- The pump motor runs too frequently.

- Because waterlogged tanks contain stagnant water, there may be unacceptable coliform results or taste and odor complaints if they are cycled frequently.

- Premature tank failure; due to water exposure, the internal walls of a waterlogged tank might corrode and weaken.

The consumer may find that replacing a waterlogged tank is the most cost-effective option.

Reasons for waterlogging

Bladder tanks become clogged with water for various reasons. The following are some of the most common causes:

- Sediment, like iron and manganese, can coat the bladder’s surface, hardening it and making it less flexible [6].

- Sediments can clog the fill or draw line, making it impossible for the tank to fill and empty normally.

- Excessive chorine levels can harm the bladder, making it fragile and less flexible.

- Tanks left directly on the ground or another wet surface can rust and lose structural integrity.

- Chlorinators can leak corrosive fumes into the tank, causing rust.

Choosing the right pressure tank size for the house

It’s critical that your pressure tank is the right size for your system. Choosing the right tank for your pumping system will help you avoid early pump failure. You can short cycle your pump if you don’t invest in the appropriate pressure tank size. When your pump turns on and off too frequently, it’s referred to as short cycling.

It consumes more energy. And since it generates too much heat, it can cause your pump to fail prematurely. Therefore, bigger is always better with pressure tanks.

The water pressure in a pressure tank is created by compressing air and applying it to the water. The pressurized air within the tank pushes the water out when a valve is opened. As a result, water is forced through the plumbing until the pressure falls to a low setting on the pressure switch.

The pressure switch causes the water pump to turn on when the low setting is reached, and additional water is pumped into the tank and house.

The drawdown (the actual amount of water stored) will increase as the tank size increases. A higher drawdown indicates a longer run duration and, as a result, fewer cycles. For optimal motor cooling, most manufacturers recommend a one-minute run duration. Pumps with one horsepower or more require longer run times.

Below are outlined the factors to have in mind when selecting the right pressure tank size:

- Gallons per minute flow rate of the pump (GPM)

- The pump’s desired run time

- Pressure switch cut-in and cut-out psi (pounds per square inch). When the system reaches the low-pressure cut-in, the pump turns on, and when the system reaches the high-pressure cut-in, the pump turns off.

The equation below can be used to calculate the amount of drawdown required based on these factors:

Pump flow rate x Run time = Tank drawdown capacity

The lowest amount of water stored and delivered by the pressure tank between pump shut-off and pump re-start is known as tank drawdown capacity. This should not be confused with “tank capacity.”

For example, depending on the pressure switch’s cut-in/cut-out (on/off) position, a 20-gallon pre-charged tank has only five-to-seven gallons drawdown capacity. Pumps with flow rates of up to 10 GPM should have a tank with a minimum drawdown capacity of one gallon per GPM delivered.

If your system includes a variable frequency drive, the equation above should not be applied. Manufacturer guidelines on tank size can be found in your manual. Majority of home pressure tanks are available in five different sizes. 20, 30, 50, 60, and 80 gallons, respectively.

Most people are unaware that pressure tanks can only contain so much water. The basic rule of thumb is to fill 1/3 of the tank with water and the remainder with air. So what is the purpose of air?

Inside the tank, the air is compressed, resulting in pressure. The air in your tank aids in moving water up and into your sinks and showers. Air is required for a pressure tank to work effectively.

Follow this simple approach to determine the right tank size.

- To begin, get two 5-gallon buckets.

- Using a yard hose, blast water into the bucket/s for precisely one minute. Just make sure there’s no other water outlet running.

- Determine the amount of water in gallons collected in one minute.

- Multiply the result by four to get the final result.

- Finally, round up the figure to get the approximate tank size.

For instance, suppose you filled your buckets with water for 1 minute and counted 6 gallons of water. Multiplying 6 by 4 yields 24. Round up to get 30 gallons as the size of storage tank required. The storage tank is proportional to the capacity of your pump.

Is a 20-gallon pressure tank big enough?

A well tank of at least 30 or 50 gallons is required for most dwellings. Unfortunately, the 20-gallon containers are often too small and are “contractor specials.” Therefore, it is advisable that you get the 30 or 50 gallon tank.

Conclusion

Bladder and pressure tanks are almost similar in function and characteristics. Both are used to extend the longevity of your pump. The only difference between them is a structural one. Bladder tanks have a bladder separating the air and water chambers while pressure tanks have diaphragms serving the same purpose.

Bladders in the bladder tank can be replaced when it wears out while the diaphragm cannot. Understanding these differences will make it easier to choose the appropriate tank for your water needs.

Michael Davis is a heating & plumbing expert who currently works as independent contractor in SC. He also writes for Plumbertip.

For almost 10 years he worked on various plumbing tasks across South Carolina.